HEATING SOLUTION / Steam Jacketed Loading Arms / Unloading Arms

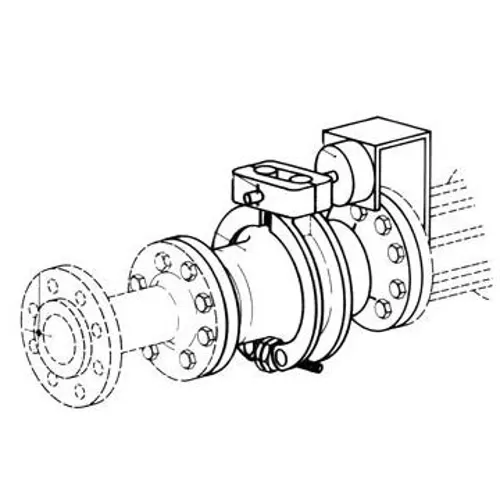

Emco Wheaton offers various heating solutions such as steam jacketed and electrical heat tracing. Based on Emco Wheaton’s extensive global experience and feedback from our customers, Emco Wheaton’s preferred solution is steam jacketed tracing.

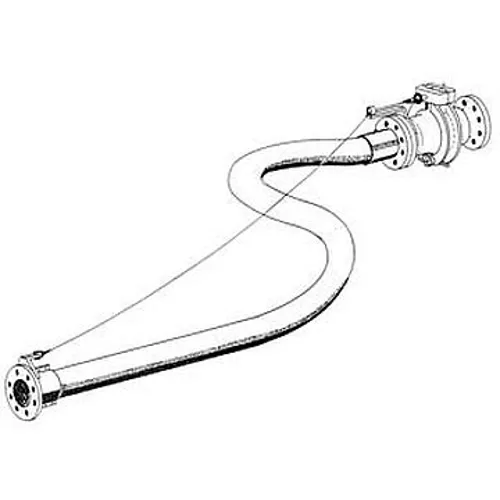

VAPOUR RECOVERY: (H2S) / Molten Sulphur Loading arms with a vapour line

Sulphur loading emits Hydrogen Sulphide Gas (H2S) when loaded into a tanker / rail wagon. During the loading process, vapour is recovered and vented to the atmosphere through a stack or an incinerator. Emco Wheaton’s loading arms are equipped with a vapour recovery line that utilizes a hose or a rigid pipeline. Based on our experience we would recommend you use a rigid pipeline that can be heated and without sulphur particles sticking to the pipe’s surface.

When hoses are not properly heated, they become stiff, and cannot be properly aligned along the loading arm. This makes maneuvering the loading arm difficult. This situation presents a high risk of sulphur particles getting crystallized inside the hose and eventually blocking or damaging the hose.

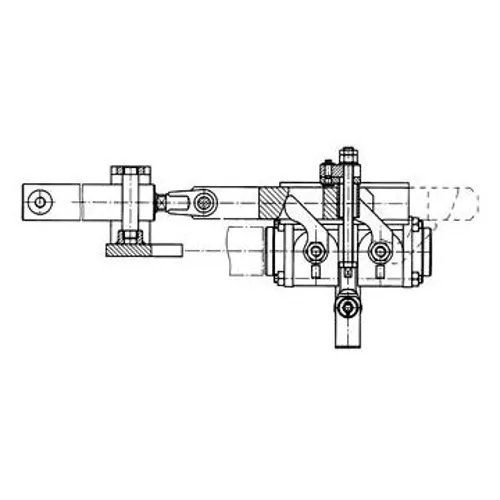

VOLUME CONTROL AND OVERFILL SAFETY / Loading arms with an electronic overfill probe

Sulphur loading volume is controlled via a weighing scale or metering. In general, a weighing scale is preferred as a primary shutoff solution. An overfill probe is installed on the drop tube of the loading arms as a secondary shutoff to avoid any over spillage in case the weighing scale/metering fails to shut off the valve. The secondary overfill device signals are connected to the Emco Wheaton control system which can also shut off the valve.

Sulphur tankers or rail wagons normally do not have overfill protection, however Emco Wheaton loading arms are equipped with an electronic overfill probe; either a tuning fork or a capacitance type. Based on customer requirements, we can include two probes for the HHL and HL loading arms.

MANEUVERING OF LOADING ARMS: HPU & CONTROL SYSTEM

Safe operation of the loading arm is very important due to its heated surface and the steam around the loading station. Since loading arms are heavy due to steam jacketing and the vapour cone, we recommend maneuvering loading arms by way of hydraulic actuation.

Emco Wheaton provides a Hydraulic Power Pack to operate the loading arms. We provide a PLC based power pack combined with the control system to monitor and control the loading arm & loading process.

The control system receives input signals from the overfill probe, grounding device, parking sensors, temperature sensors, and loading valve (shut off) positions. The system provides one permissive load signal to operate the pump and loading valve. The system can also provide or replicate the signals to the customer’s DCS.

The control panel includes status lamps, pushbuttons, emergency shut down and alarm lamps. Also, the control panel can be customized as per customer/project requirements.